1, the phenomenon described

Customer product design, the need to use crimping way to fix the metal pillars (shown in Figure 1), each piece of product requires crimping 60 metal pillars. Requires crimping smooth without floating high. Customers in the previous factory manufacturing, the daily delivery of only 50PCS products, and because of crimping when prone to crack, resulting in about 2% of the scrap rate.

一

2, the reasons for the analysis

The customer's product batch is usually 100-300PCS, is not conducive to the use of automatic equipment crimping; before the factory using manual crimping, daily pressure on the metal pillars 3000 or so, and there is a high scrap rate. Thus, the key point to solve the efficiency and scrap rate is to improve the copper pillar crimping link.

3, to improve countermeasures

After the understanding of the role of copper pillars in the customer's products, this copper pillar is a fixed fulcrum for the power tube. Need to ensure the overall formation of copper pillars and reliability. By communicating with the customer, it is recommended to change the crimping process to the through-hole patch process. Related as follows:

(1) PCB through-hole expansion 0.1mm, to ensure that the copper pillars can be manually inserted into the hole, but at the same time to ensure that can not shake around.

(2) steel mesh openings in accordance with through-hole pad 90% open ring hole.

(3) the copper column for SMT chip process, the use of manual placement (copper column structure is not suitable for machine placement).

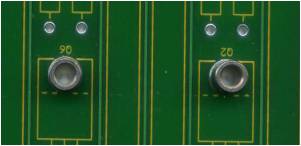

(4) reflow soldering temperature control at 245 degrees (lead-free process), the product furnace spacing to maintain 10cm. Ensure that the solder is completely wetted. (Through-hole reflow soldering effect shown in Figure 2)

二

4, the effect of verification

(1) Product manufacturing efficiency increased by 500%.

(2) product scrap rate of 0%.

Through the process of adjustment, manufacturing costs significantly reduced, we have a price adjustment for customers.

Take the initiative to provide customers with professional products manufacturing solutions for customers to save costs in order to get customer recognition.